LIVE TESTING HEAVY MACHINERY

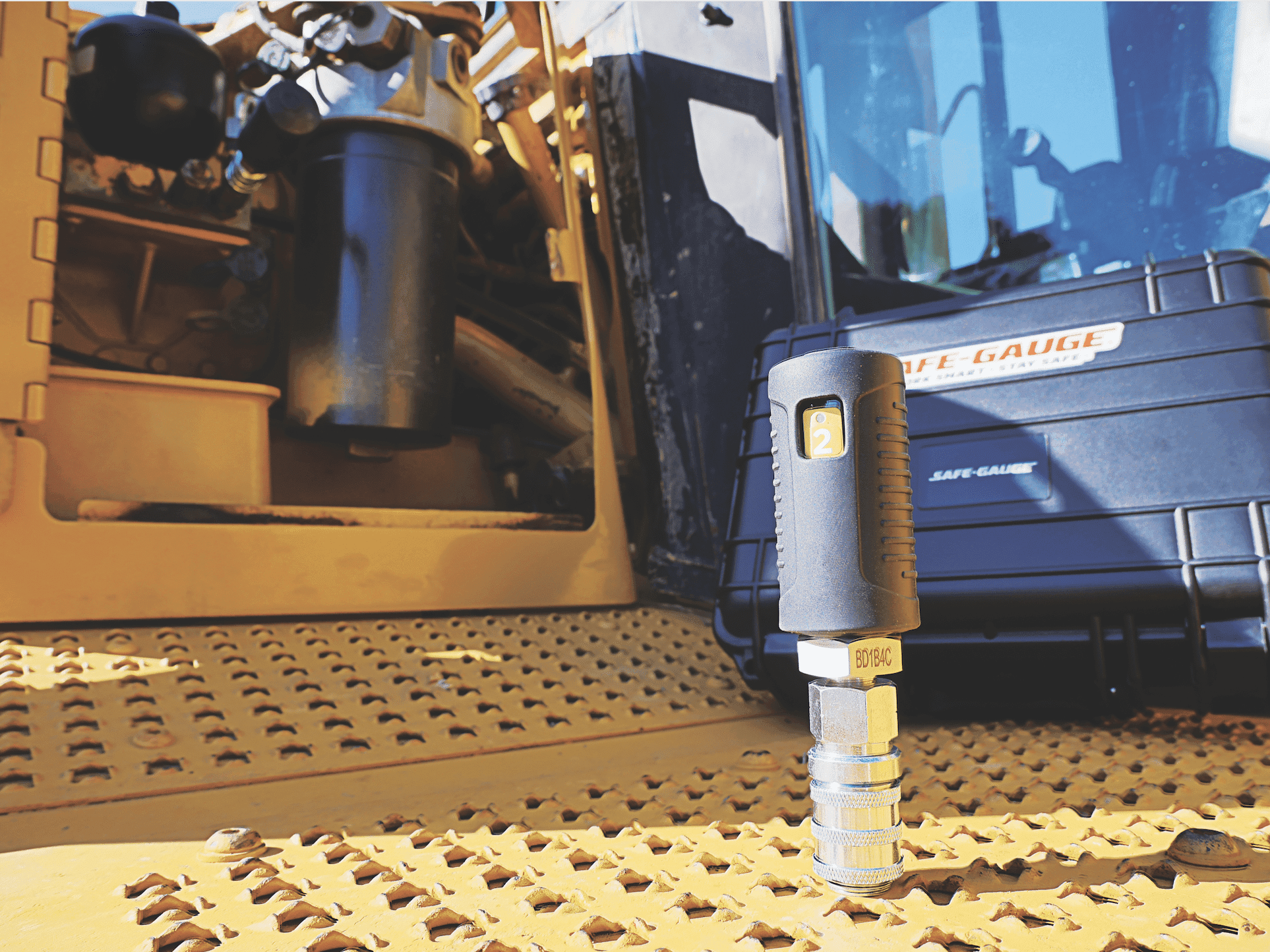

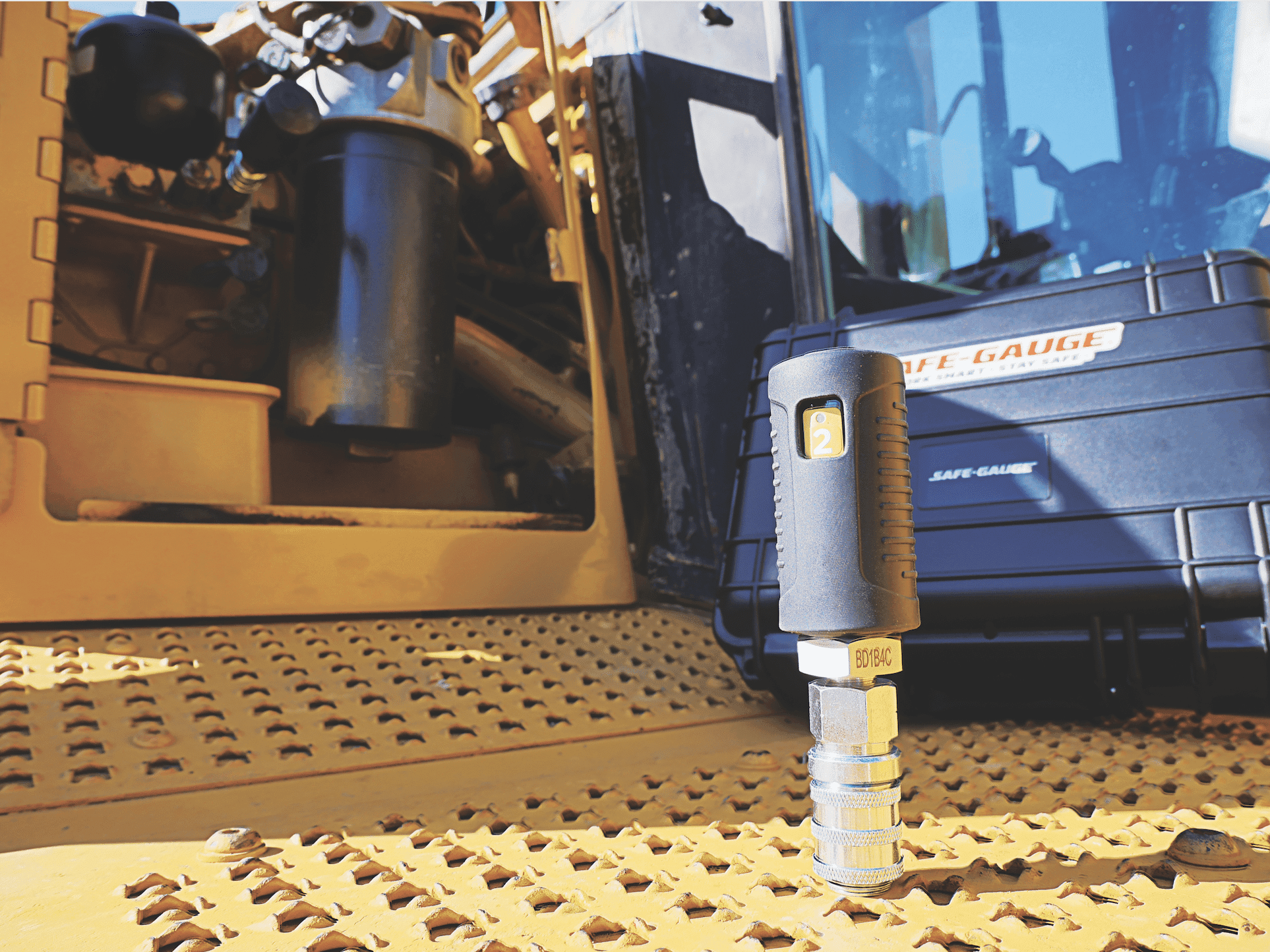

Our mission is to ensure that no one has to risk their safety.

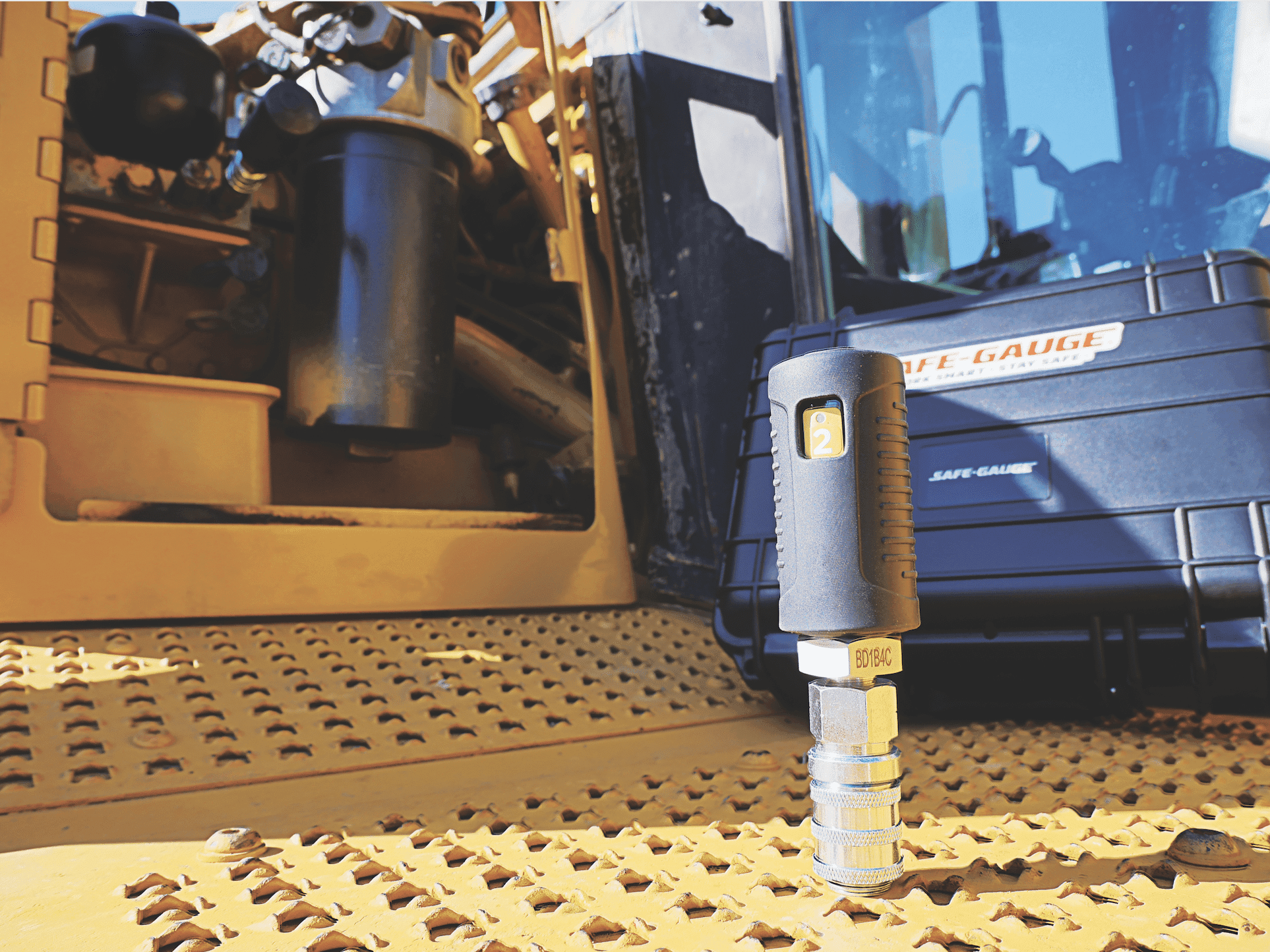

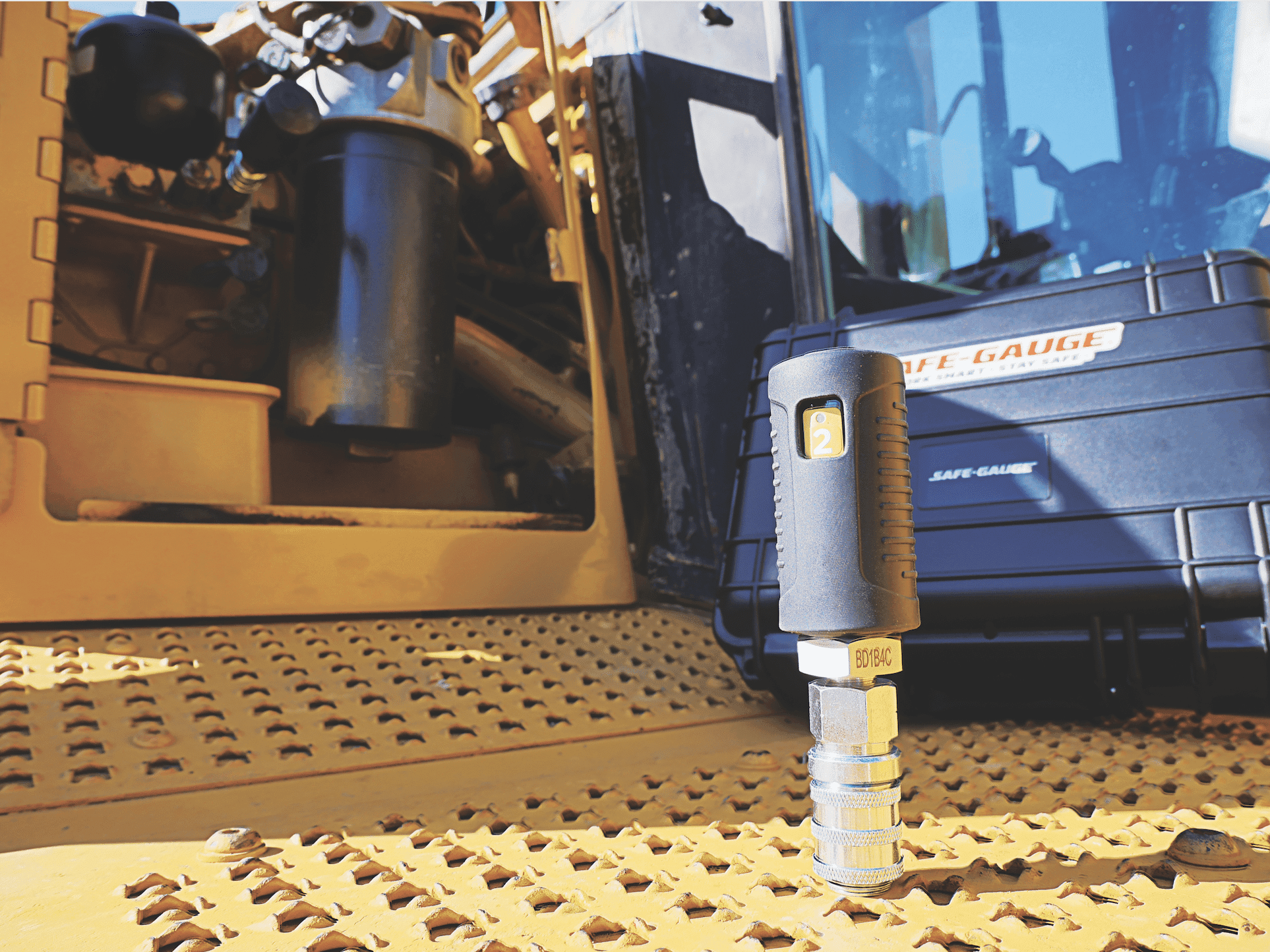

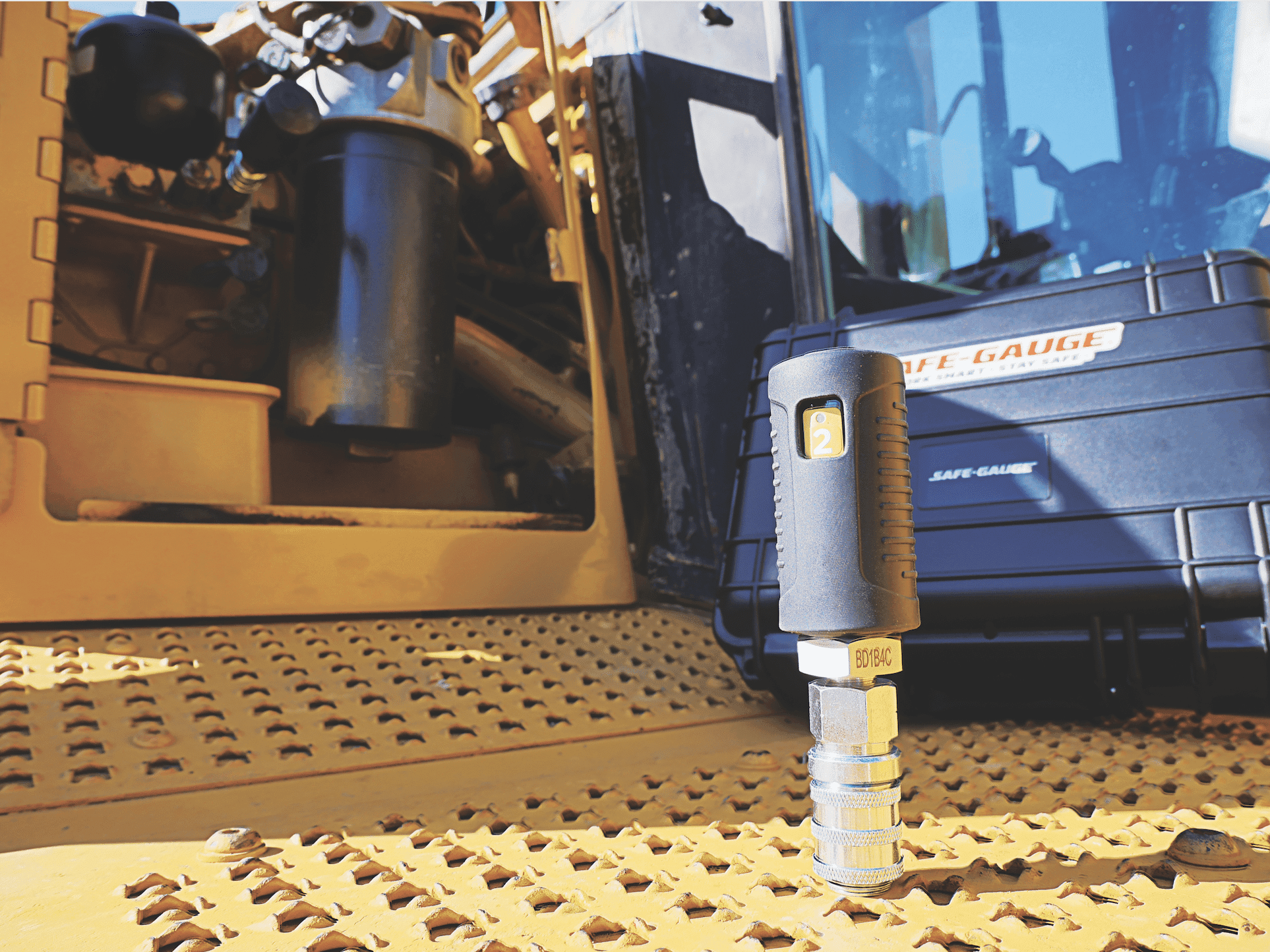

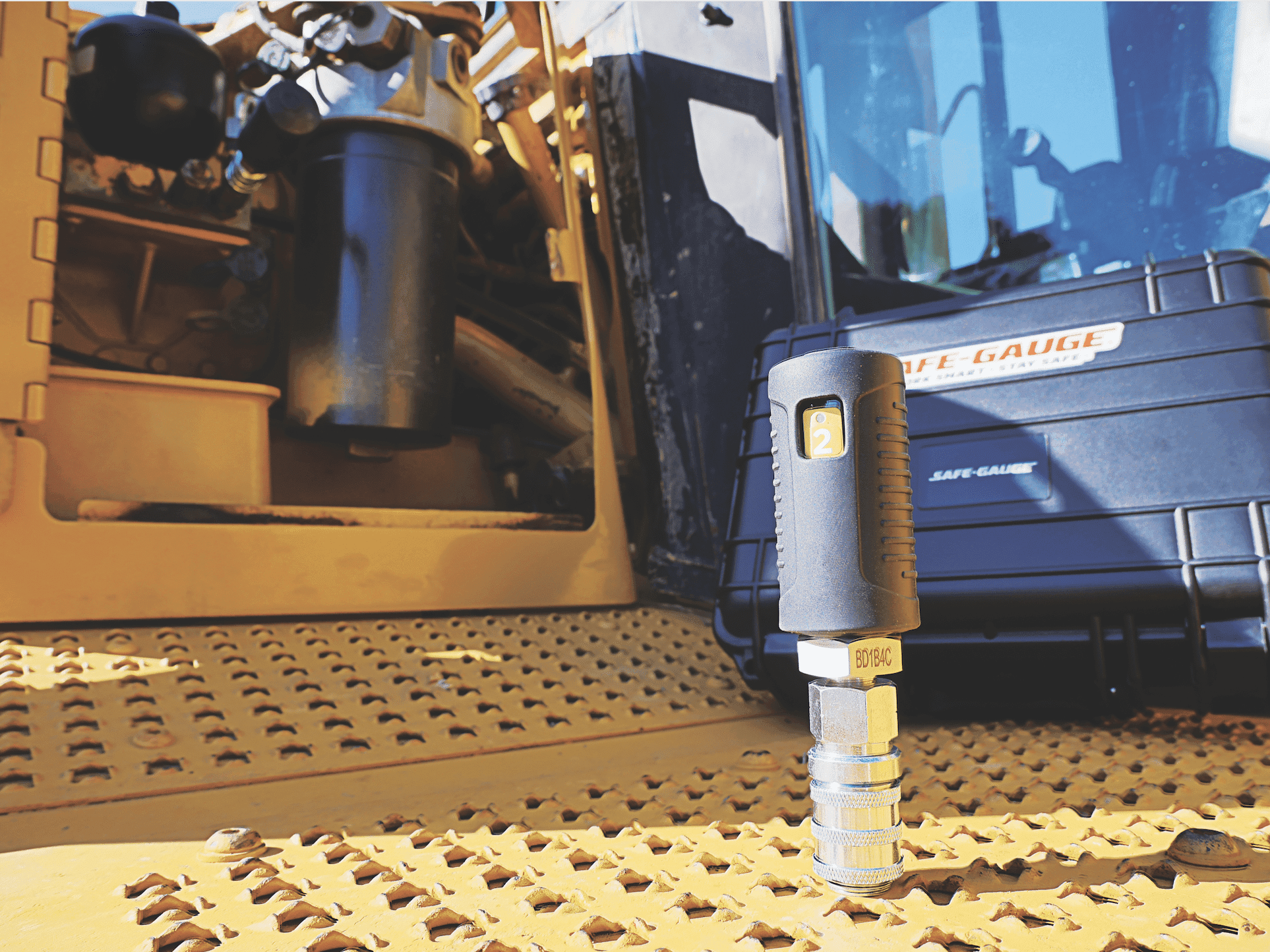

Ensure that no one has to risk their safety when live testing heavy machinery

OUR STORY

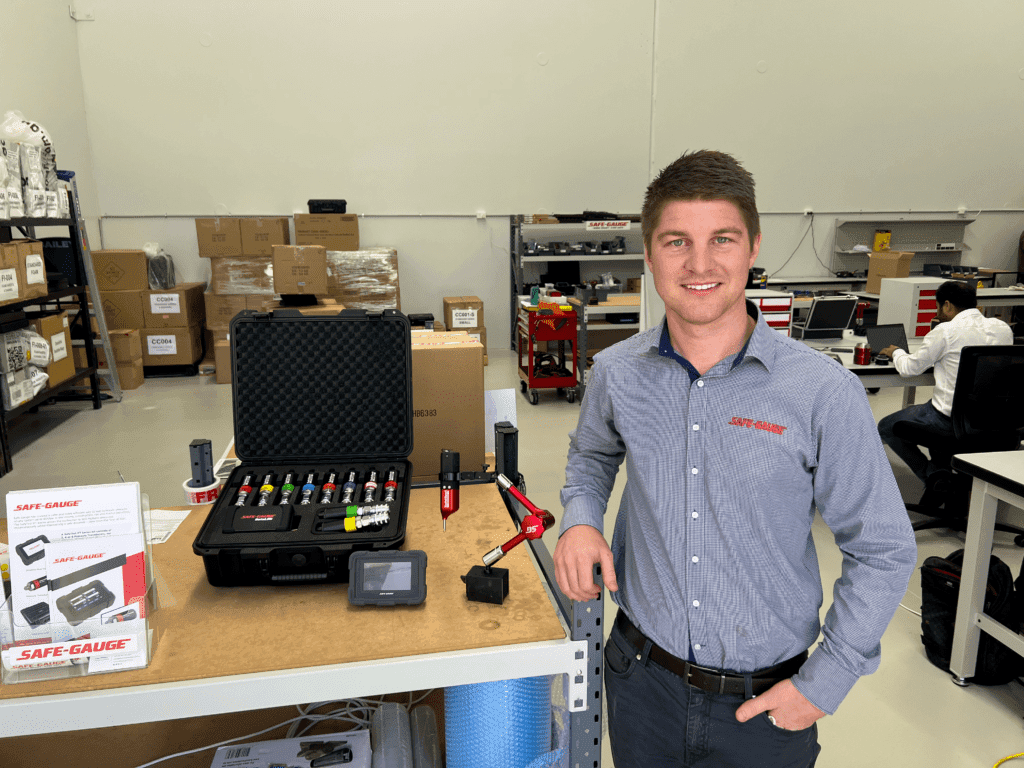

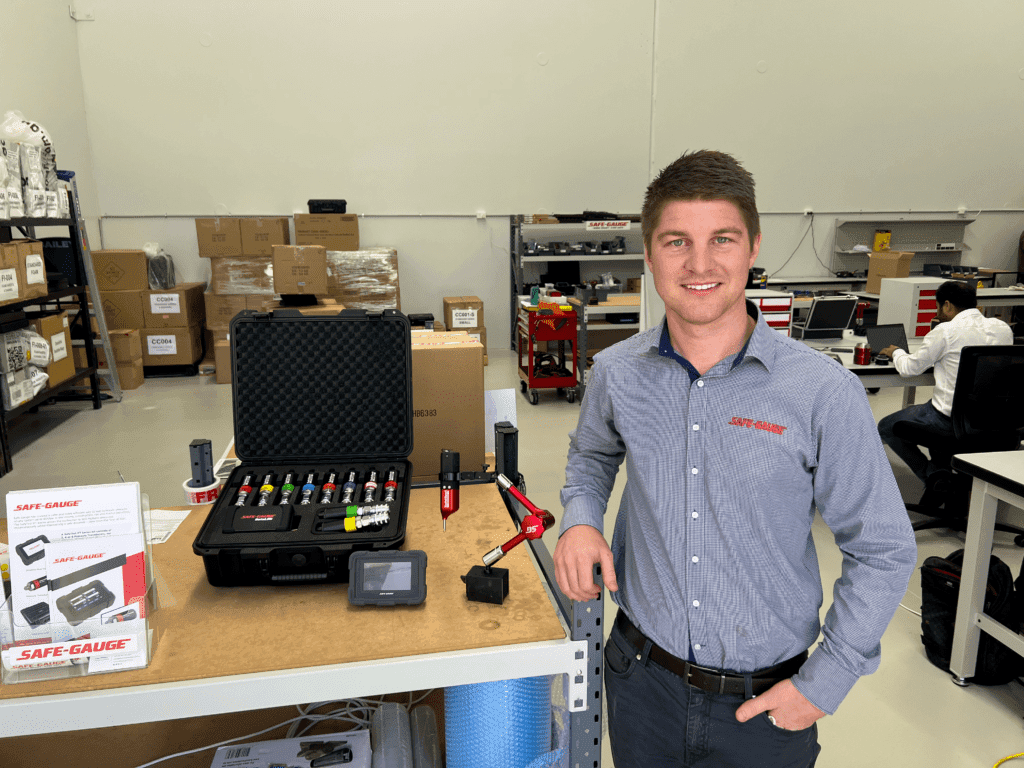

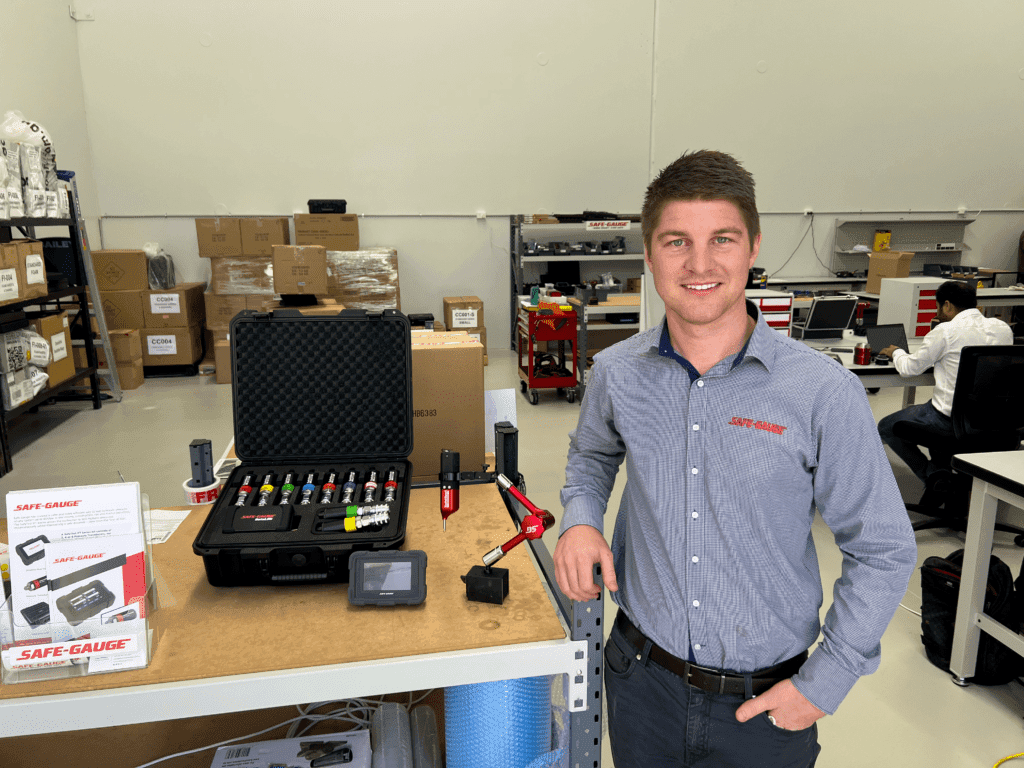

SafeGauge was founded by Managing Director Luke Dawson in 2019, who spent 10 years working on heavy machinery as a heavy plant mechanic in the Australian mining industry.

Concerned by the significant risks involved in machinery live work, he began working to develop wireless testing solutions designed to minimize the danger with high-risk work.

Our teams passion and commitment to safety, performance,

and efficiency has been the driving force behind SafeGauge, which is now gaining recognition from leading global industry bodies.

Today, SafeGauge proudly remains Australian-owned, with sales spanning over 15 countries. Supported by a global distribution network, the company continues to champion safer working practices in heavy industries worldwide.

SafeGauge was founded by Managing Director Luke Dawson in 2019, who spent 10 years working on heavy machinery as a heavy plant mechanic in the Australian mining industry.

Concerned by the significant risks involved in machinery live work, he began working to develop wireless testing solutions designed to minimize the danger with high-risk work.

Our teams passion and commitment to safety, performance, and efficiency has been the driving force behind SafeGauge, which is now gaining recognition from leading global industry bodies.

Today, SafeGauge proudly remains Australian-owned, with sales spanning over 15 countries. Supported by a global distribution network, the company continues to champion safer working practices in heavy industries worldwide.

OUR HISTORY

2019

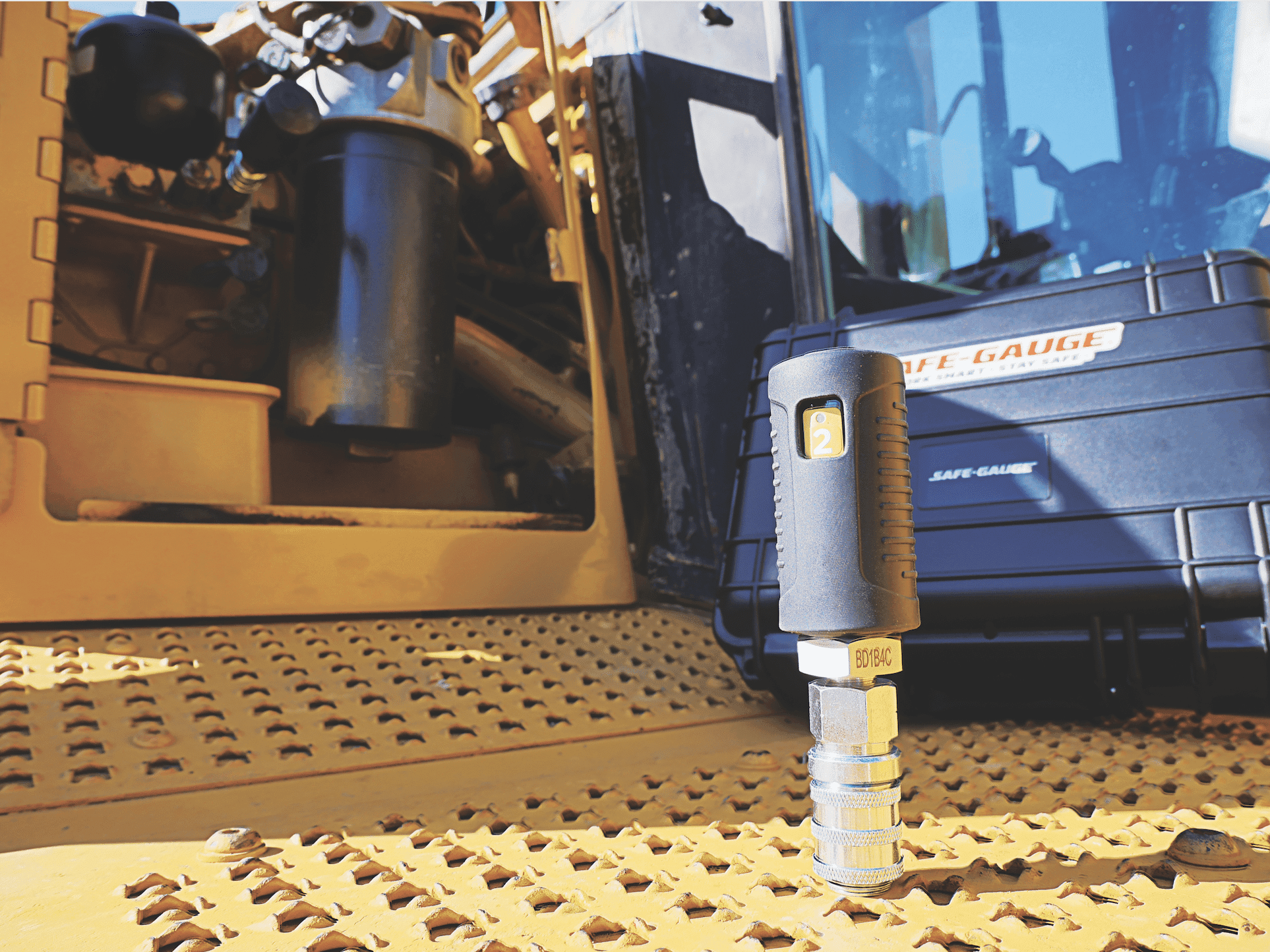

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

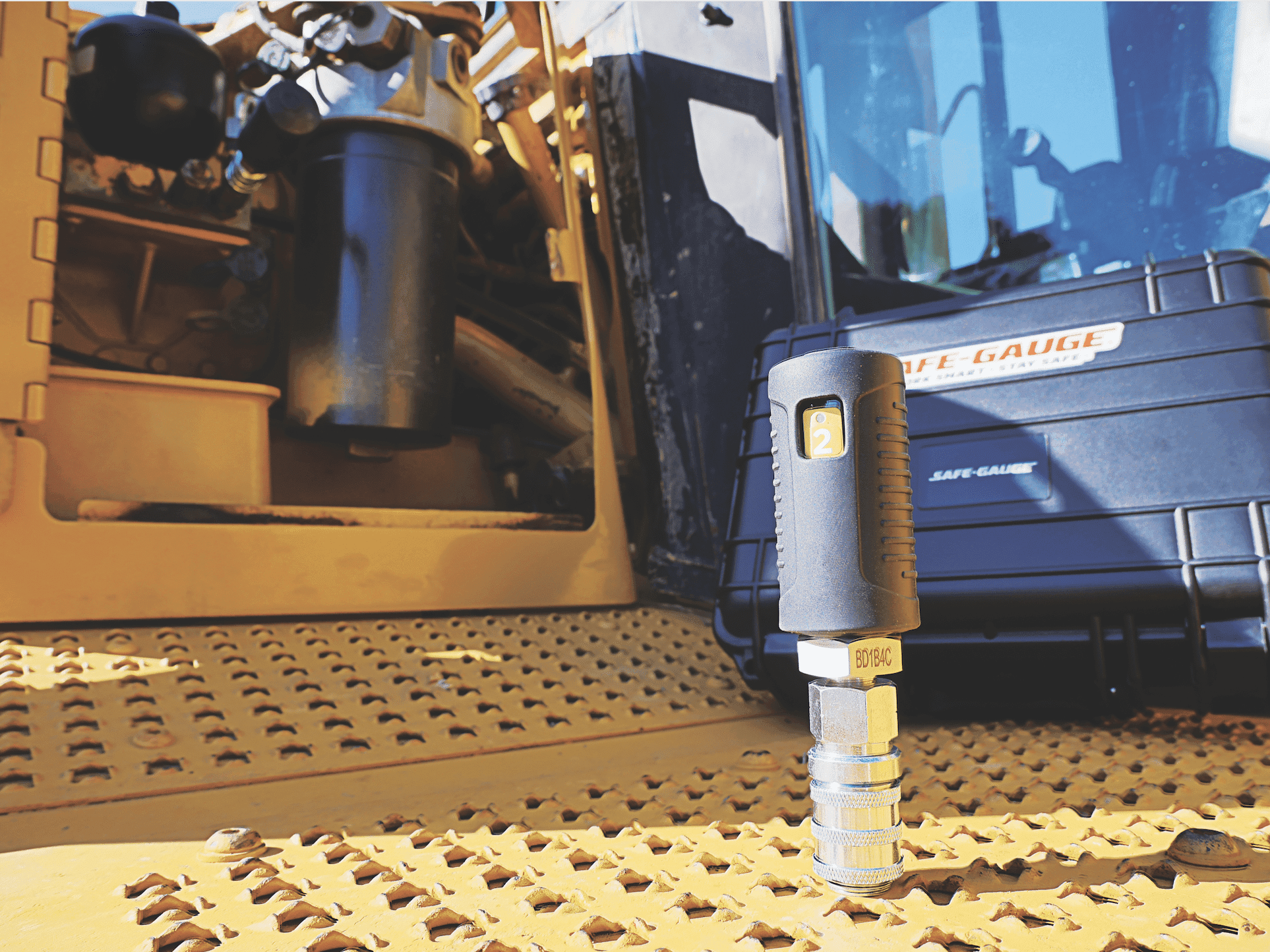

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

2019

The concept for the first SafeGauge product came from Luke completing a Steering & Clutch calibration on a D11 dozer, using four tetra gauges running into the "hell hole" of the machine.

2019

SafeGauge was established on 27th of March 2019 to pursue the development of a safer way to test high pressure hydraulic systems. Luke worked with Steve Chick who is today our senior engineer, to develop the wireless pressure transducer and MultiTool which was tested and proven on site with BHP, Mt Arthur Coal.

2019

The wireless tooling design received BHP "Bright Spot" recognition, which gained attention from other sites and mining organizations throughout Australia.

2020

Partnerships between trusted Australian manufacturers and suppliers were formed to establish our supply chain which still stand strong today.

2020

The one prototype available was used for demonstrations to sell the first production 50 kits throughout Australia during the initial challenges presented by Covid-19

2020

Established a customer base of tier 1 mining companies and OEM's. Awarded the highly commended Startup of the Year by Hunter Manufacturing Awards helping grow the team from two to four.

2021

Moved into a shared facility with the Melt Accelerator, in Warners Bay, NSW. This was our first office and warehouse where we established initial design, production supply chain processes.

2021

Working with our customers on new "live work" safety challenges drove us to start the development of new solutions. Next, we designed a wireless Dial Indicator working with a Newcastle University student for their final year engineering project.

2021

Closed our first capital raise seed round with funding of $1.6M supported by the Sydney Angels, Pipeline Capital, and other individual investors. Growing to a team of six.

2022

The Dial Indicator was released to market with a large uptake from existing and new customers. Several improvements from the original version where quickly brought to market responding to customer feedback.

2022

Industry feedback encouraged us to design the Tachometer and a new version of the PT with greater accuracy and reliability. Growing our team and capability to design what our customers need with increased speed to market.

2022

Awarded winner for the NSW Mineral Council Small business of the year, HMA Excellence in Product Design award and Good Design Australia. Expanding to a team of ten.

2023

Customers who required data capture and reporting helped our team develop the MultiTool Pro, launched at IMARC (International Mining And Resources Conference). This provided further safety benefits, efficiency gains and accurate data capture helping provide more value to the user.

2023

Established a distribution network in North America, South America and South Africa through trusted partners. With stock held in >10 countries, helped provided needed solutions to the global market. Western Australia CORE Hot 30 award winner for Equipment Innovation.

2023

Collaboration with South Metro TAFE, Westrac training institute and others to help train the next generation of Heavy Vehicle technicians using SafeGauge tooling.

2024

New office opened in Arizona USA, seeing Founder Luke Dawson relocate to continue driving global growth through existing distributors and OEM partnerships.

2024

The Push Rod, Laser Measurement, next Gen Pressure Transducer and the SafeGauge App where released to market. Suitable for a broader range of the industry, including affordable entry-level options for individuals.

2024

Major rollout with Hastings Deering CAT throughout Queensland and Northern Territory, Australia. Providing bespoke kits to all branch facilities and field service vehicles.

2024

Westrac CAT officially offering SafeGauge product as a partner thougout New South Wales and Western Australia. Offering ad-on options for new machine purchases and ongoing maintenance tooling.

OUR TEAM

OUR TEAM

Luke Dawson

Founder & Managing Director

Greg Sweeney

General Manager

Belinda Jackson

Procurement and Production Manager

Stephanie Dawson

Marketing / Business Account Manager - Global

Nicholas Packham

Business Development Manager

Harrison Bergman

Business Development Manager

Rebecca Dawson

Finance & Administration Manager

Steve Chick

Senior Engineer

Scott Olero

Electrical Engineer

Hasham Khan

Mechatronics Engineer

Dan Hawkins

Product Specialist

Augustin Lourdunathan

Software Engineer

Josh Kruik

Quality Engineer

Parisa Hajibabaei

Production Planner & Purchasing Coordinator

Mandi Page

Senior Production Technician

Vincent Matongo

Production Engineer

Mohammed Feroz

Production Technician

Sean Dillon

Storeman

Krystal Johnson

Production Technician

Linda Lawson

Production Technician

OUR VALUES

SAFETY ALWAYS

COMES FIRST

INTEGRITY

AND ETHICS

EXCELLENCE

IN QUALITY

INNOVATION &

ADAPTABILITY

UPHOLD A CUSTOMER

-CENTRIC APPROACH

COLLABORATION

AND TEAMWORK

Ensuring that no one has to risk their safety when live testing heavy machinery

All rights reserved © SafeGauge

2024

Website design by Outshine.design

Ensuring that no one has to risk their safety when live testing heavy machinery

All rights reserved © SafeGauge

2024

Website design by Outshine.design

Ensuring that no one has to risk their safety when live testing heavy machinery

All rights reserved © SafeGauge

2024

Website design by Outshine.design